Most of the visitors that are in search of a metal world map are aware that specialised machinery is required for their production, particularly for precise cut and engraved stainless steel maps. Coupled with the continual rise in steel prices, these maps have become some of the most exclusive options available. However, their aesthetics perfectly align with their price, exuding luxury and sophistication.

Preparing the stainless steel

Before delving into the cutting and engraving process, the stainless steel must undergo preparation. This means sanding the steel with ceramic beads, a task normally handled by our steel supplier. This ceramic blasting method uses minute ceramic beads, ensuring even the hardest steel surfaces, such as magnetic stainless steel, are rendered smooth. Due to the specialised nature of this technique, we entrust it to experts rather than maintaining an in-house sanding booth.

Furthermore, both sides of the steel plate are blasted to prevent tension in the metal. If only one side were treated, tension could arise, causing the plate to bend. This warping could occur during the cutting process, particularly with larger continents. To prevent such bending, the back of the map is also blasted.

Once both sides of the stainless steel plate have been blasted, a special oil is sprayed onto the top side. This oil serves to shield the surface from sparks and tiny metal fragments that may be generated when the laser begins cutting or engraving at specific points.

Cutting and engraving with the fiber laser

Once the base material, in this instance stainless steel, is prepared, the entire steel plate is placed on the laser bed of the fiber laser machine. After determining the precise parameters, the cutting and engraving process begins. In the featured image, you can witness the sparks emanating from the steel as the laser makes contact. You might have noticed that the homepage’s header showcases a repetitive video displaying the laser’s operation. As you can also see, is that the steel looks almost white. That’s because all footage was made from outside a protective glass filter panel.

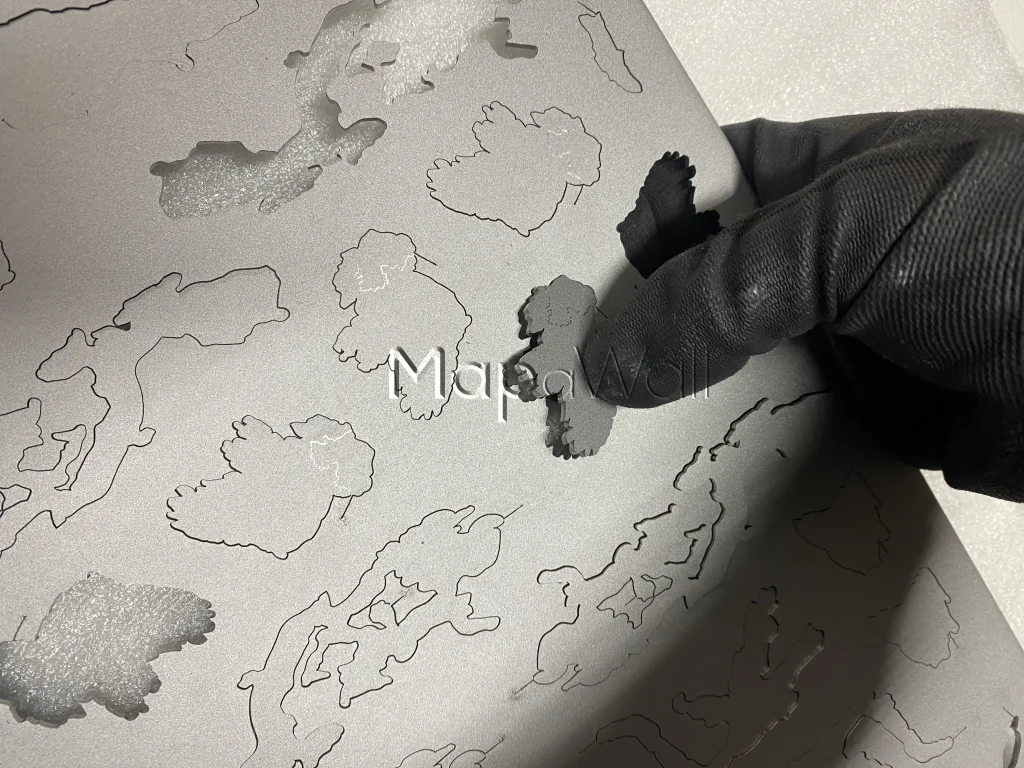

Upon completing the cutting and engraving of the continents, the fiber laser proceeds to work on the islands. These smaller parts are not cut all the way through; doing so would cause them to drop immediately into the reservoir beneath the laser bed. Retrieving the islands from beneath the laser bed is manageable; however, there is a risk of damage if they fall onto other metal parts or cutouts. Therefore, we set the parameters to cut the contours of the islands until only a fraction of a millimetre remains. This ensures that all islands remain connected to the plate and wont fall down.

This is only the first part of how the stainless steel world map is made. In order to get it ready to be shipped with our carrier, quite a few other steps need to be done. In another post we will have a closer look at the cleaning and preparing the map for the client process. Stay tuned!

Leave a Reply